- Home

- IRMCO

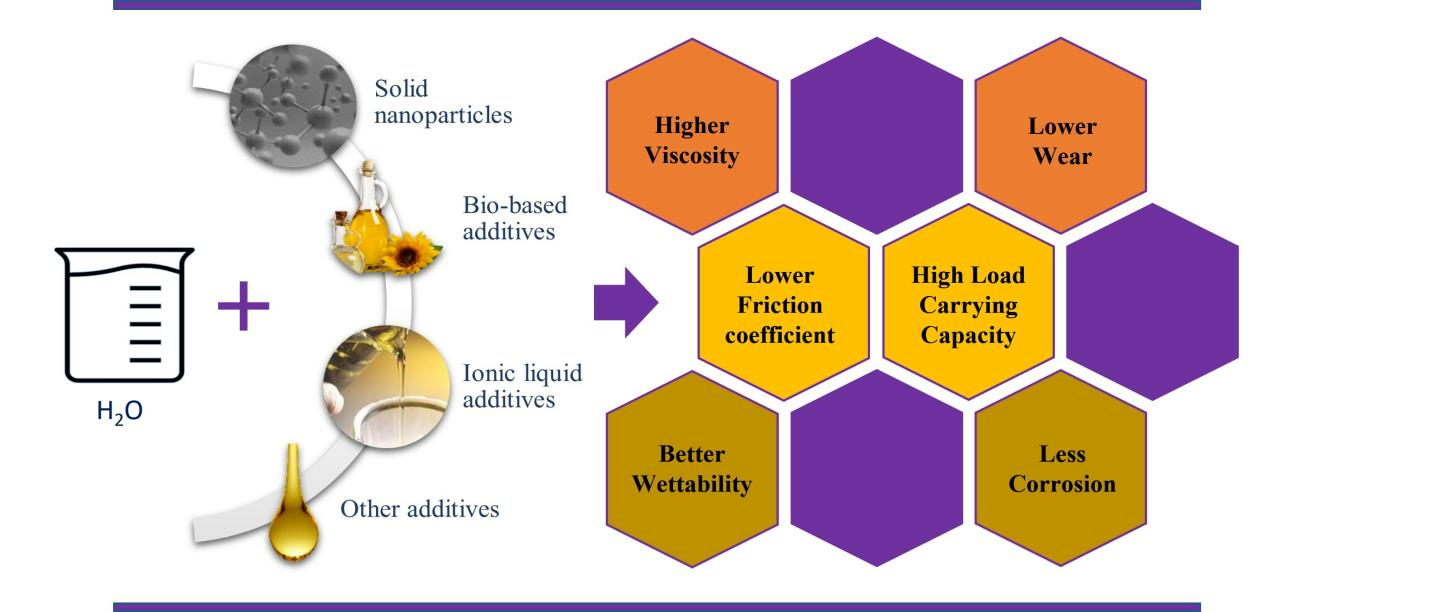

Benefits of Water-Soluble Lubricants

Easier Cleaning

- Water-soluble lubricants can be rinsed off easily with water or mild detergents.

- Reduces or eliminates the need for harsh solvents or multiple cleaning stages.

Reduced Cleaning Costs

- Lower consumption of cleaning chemicals.

- Less energy required (e.g., lower temperature washing).

- Decreased water treatment costs due to lower chemical contamination in effluents.

Time Savings

- Faster cleaning cycles mean higher throughput and reduced lead time

- Simplified cleaning process improves workflow efficiency

Environmental & Worker Safety Benefits

- Less hazardous than solvent-based cleaning.

- Reduces VOC emissions and improves workplace safety.

Improved Coating Quality

- Cleaner surfaces lead to better adhesion and fewer coating defects.

- Reduces the rate of rework or rejection.

Summary Table

| Aspects | Oil-Based Lubricants | Water-Soluble Lubricants |

|---|---|---|

| Cleaning Difficulty | High (requires solvents) | Cleaning Difficulty High (requires solvents) Low (rinsable with water) |

| Cost of Cleaning | High | Lower |

| VOC Emissions | High | Low |

| Coating Adhesion | Often poor due to residues | Improved |

| Equipment Wear | May require additional degreasing equipment | Reduced complexity |

| Rework/Reject Rates | Higher | Lower |

Final Thoughts

Switching to water-soluble lubricants in processes can significantly:

- Reduce operational costs

- Improve coating quality

- Increase production efficiency

This makes them a smart choice for industries looking to streamline their finishing operations while maintaining high standards for product appearance and durability.

Industry Leading Performance

IRMCO GEL has become the benchmark lubricant for mandrel tube and pipe bending worldwide. IRMCO are the only company with 4 non-oil metal forming aerospace approvals.

Reduced Tooling Cost & Down Time

IRMCO FLUIDS provide optimal protection for tooling surfaces and parts – reducing wear and downtime related to maintenance. The improvements to tool life result in increased efficiencies and line speeds.

Clean Running

IRMCO FLUIDS offer improved part cleanliness and weld-through capability over oil based chemistries. In many instances, pre-treatment process bath life can be increased and cleaning temperatures can be reduced – saving energy and improving safety.

Welding, Assembly, Cleaning and Painting

In most cases, parts formed with IRMCO products can be welded or assembled without prior cleaning, providing significant energy and process efficiency savings. IRMCO lubricants have the highest rating for reducing paint defects, caused by residual lubricant.