- Home

- Pressing

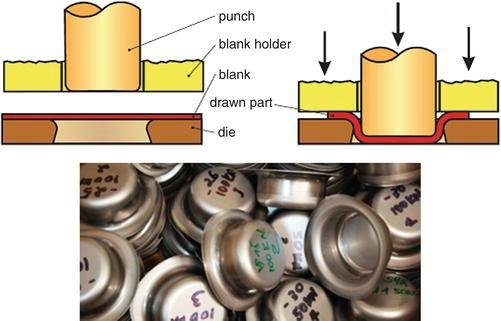

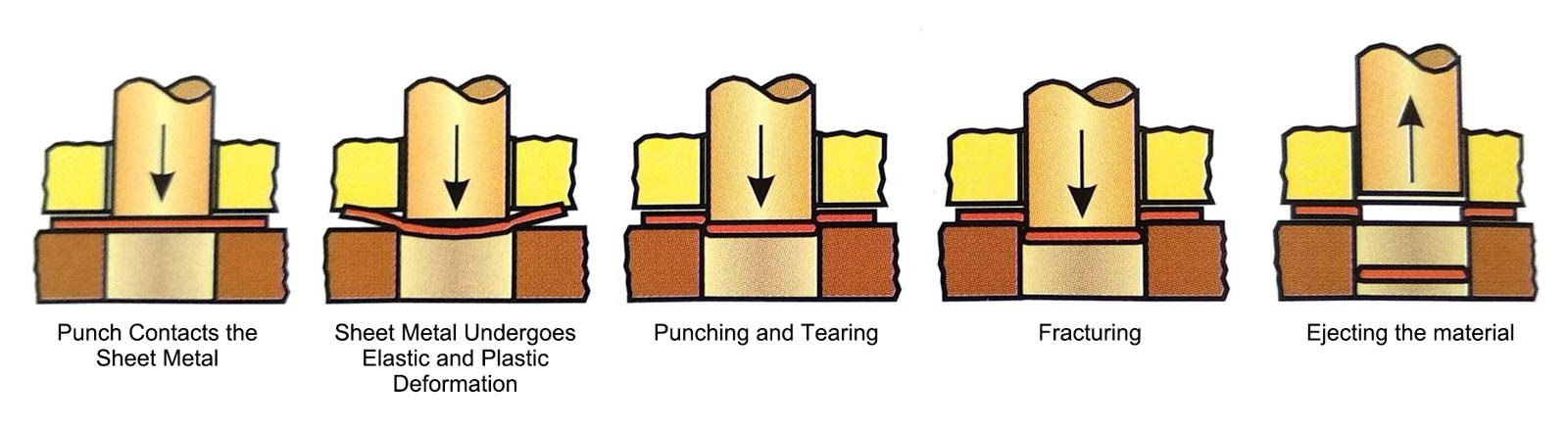

In sheet forming, lubrication involves applying fluids or pastes between the metal sheet and the die to create a protective layer that reduces friction, prevents metal adhesion, dissipates heat, and controls material flow, ultimately improving part quality and tool longevity. The process involves selecting the appropriate lubricant type (oils, pastes, or gels), applying it to the workpiece or into the die, and often includes a post-forming cleaning step to remove residue, especially for parts intended for subsequent coating or surface treatments.

Please Click Here to watch the video.

Key Aspects of the Process

Lubricant Selection

Type:Lubricants can be neat oils, water-based gels, or pastes.

Additives: Extreme Pressure (EP) additives like sulfur, chlorine, or phosphorus react with the metal surface to form a protective film.

Application: The choice depends on the process (e.g., drawing, bending), the material being formed (e.g., AHSS), and whether residue is acceptable.

Application Methods

Manual Application: Pastes can be smeared onto the sheet surface before forming.

Automated Systems:Some systems use integrated lubrication channels within the die to deliver the lubricant to high-stress areas.

Mechanism of Action

Reduced Friction: The lubricant creates a film that separates the die and the workpiece, minimizing friction.

Adhesive Wear Prevention: It prevents direct metal-to-metal contact, which can cause material to adhere to the die.

Heat Dissipation: Lubricants help to absorb and carry away heat generated during the deformation process.

Strain Control:Lubrication can influence metal flow and help to redistribute strains, improving formability.

Post-Forming Steps

Cleaning:After the part is formed, the lubricant must often be removed to ensure proper surface preparation for subsequent processes like painting or coating.

Residue Management:In open-loop systems common in sheet forming, a significant amount of lubricant is consumed by the deformed material and remains on the part, necessitating an efficient removal process.

Factors Influencing Lubrication

Material Surface Roughness:The lubricant needs to fill the valleys of the metal surface, with the fluid reaching the peaks to reduce friction effectively.

Forming Speed & Pressure:These factors influence the effectiveness of the lubricating film.

Advantages of Using Water-Soluble Lubricants in Progressive Stamping

- Cost-Effective: Can be diluted with water, lowering overall lubricant usage and cost.

- Environmentally Friendly: Many are biodegradable and easier to dispose of compared to oil-based types.

- Improved Cleanability: Easier to wash off parts and dies; reduces post-processing time and cost.

- Better Cooling Properties: Reduces thermal deformation and helps maintain dimensional stability.

- Reduced Fire Hazard: Unlike oil-based lubricants, they’re non-flammable, improving workplace safety.

- Enhanced Tool Life: By minimizing heat and friction, tooling lasts longer.

- Less Residue:Promotes better adhesion in downstream operations like painting or welding.

- Operator-Friendly: Low odor and lower misting reduce operator discomfort and health risks.

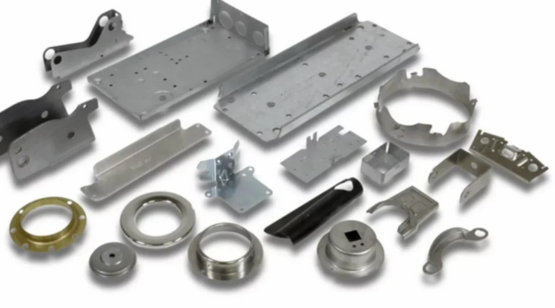

Common Applications in Stamping

- Electrical components

- Automotive parts

- Consumer electronics

- Medical device housings

Water-soluble lubricants offer a smart, efficient, and cleaner solution for the progressive stamping process. Their ability to reduce friction and heat while supporting downstream operations like coating and welding makes them ideal for modern, high-precision manufacturing environments.