- Home

- Tube Bending

Tube bending and Lubrication

Lubricating a tube during cold bending is crucial to reduce friction, which prevents metal buildup, galling, and excessive tool wear, thereby protecting the tube's surface and the bending tools. It also helps maintain the tube's shape and achieve precise bends by ensuring smooth movement and reducing slip. Using proper lubricants leads to higher quality finished parts, extends tool life, and makes the overall process more efficient and economical.

Key Benefits of Lubrication

Reduced Friction and Wear

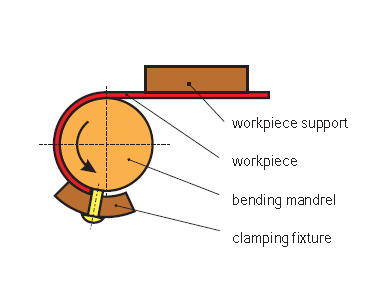

The primary role of lubrication is to act as a barrier between the tube and the bending tools (such as the mandrel, die, and wiper die). This significantly lowers friction, preventing metal particles from being trapped, which can lead to galling and wear on both the tube and the tooling.

Tool Protection

By minimizing friction and metal pickup, lubricants extend the lifespan of the bending dies, mandrels, and other components, reducing maintenance and replacement costs.

Improved Surface Quality

Proper lubrication protects the surface of the tubing from marring or damage during the bending process, ensuring a clean and high-quality finished product.

Enhanced Accuracy and Precision

Lubrication helps the tube slide smoothly through the bender, reducing slip and preventing misalignment. This allows for the maintenance of precise angles and shapes, critical for the part's functionality.

Increased Efficiency and Cost Savings

A well-lubricated bending process is more efficient, requiring less effort and reducing downtime associated with tool wear or part defects.

Preventing Tooling Issues

Adequate lubrication helps prevent other issues like wrinkling by ensuring proper contact and pressure during bending.

How it works with IRMCO

IRMCO is pioneered the art of lubricating the tubes by means of liquid and gel. Both the products are Water soluble, environmental friendly and user friendly. These products are water soluble so no more harsh detergents or tricky phospheting process are needed to clean the tube once bend. Once the tube is bend rinse it with plain simple water and the residue are gone. For more details get in touch with Subject Matter Experts ( ashish@tecmec.in ) from IRMCO India.

Recommended for Steel, Stainless Steel, High strength steel, exotic material for aerospace and defense markets.

Application areas : Aerospace, Automobile, Food processing units, Pharmaceutical equipment manufacturing, Semiconductors, boilers, hydraulics etc.